Are you aware of the many ways PUF sandwich panels are transforming modern construction?

As the demands of the building industry evolve, innovation becomes essential to meet changing performance, energy, and sustainability needs. PUF sandwich panels have emerged as one of the smartest, most versatile solutions in this space — offering efficiency, durability, and design flexibility across a wide range of industrial applications.

In this blog, we’ll explore what makes PUF sandwich panels so popular and how they’re being used across different industries today.

🔍 What Are PUF Sandwich Panels and Why Are They So Popular?

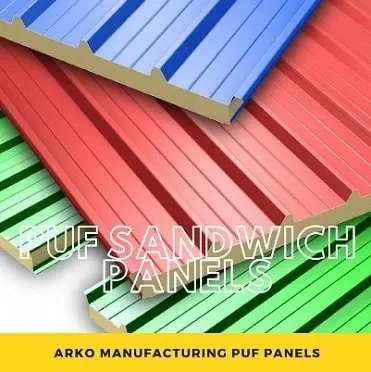

PUF (Polyurethane Foam) sandwich panels consist of a rigid polyurethane foam core sandwiched between two layers of protective materials — usually metal sheets. Depending on the intended use, these facing materials can vary (GI, aluminum, stainless steel, etc.), giving the panels different structural and aesthetic properties.

Here’s what makes PUF panels a standout choice in construction:

Lightweight yet durable: Easy to handle and install while maintaining high structural strength.

Excellent thermal insulation: The PU foam core minimizes heat transfer, maintaining optimal indoor temperatures.

Quick installation: Prefabricated design reduces on-site labor and construction time.

High load-bearing strength: Performs better than traditional walls and roofing in many industrial settings.

Weather and moisture resistance: Suitable for all climates; corrosion-resistant and low-maintenance.

Sound and fire insulation: Offers excellent acoustic performance and fire-retardant options.

Cost-effective: Faster project completion reduces overall expenses.

Eco-friendly: Energy-efficient design supports green and sustainable construction goals.

Aesthetic appeal: Available in a range of colors, finishes, and coatings for attractive façades.

These combined advantages explain why industries worldwide are shifting toward PUF sandwich panels as the modern alternative to conventional construction.

🏭 Applications of PUF Sandwich Panels Across Industries

PUF sandwich panels have become the go-to solution for walls, roofs, ceilings, and enclosures in both industrial and commercial settings. Let’s look at how different industries are using them:

1. Green Buildings

PUF panels contribute to sustainable construction by drastically reducing operational energy use. Their high insulation efficiency lowers HVAC loads, making them ideal for IGBC and LEED-compliant green building projects.

2. Cold Storage & Cool Rooms

With exceptional insulation and airtightness, PUF panels are indispensable for cold chain infrastructure. They’re used in cold storages, modular cool rooms, and temperature-controlled enclosures across the food, pharma, and logistics sectors.

3. Frozen Food Processing Rooms

In industries such as food processing, dairy, floriculture, and fruit ripening, maintaining consistent low temperatures is crucial. PUF panels ensure this stability while preventing moisture buildup, keeping facilities hygienic and efficient.

4. Industrial Buildings

From warehouses to manufacturing plants, PUF panels provide structural strength and protect sensitive equipment from temperature fluctuations and environmental factors — ensuring better working conditions and longer machinery life.

5. Commercial Spaces

In showrooms, offices, and retail outlets, PUF panels offer an attractive combination of design flexibility, cost-efficiency, and thermal comfort. Their sleek finishes make them perfect for modern façade and cladding applications.

6. Prefabricated Homes & Shelters

For prefab housing projects, site offices, and emergency shelters, PUF panels allow quick assembly, low maintenance, and high durability — ideal for remote or temporary installations.

7. Hospitals & Healthcare Facilities

Healthcare environments require precise temperature and noise control. PUF panels help maintain sterile, climate-stable conditions in hospitals, clinics, laboratories, and diagnostic centers, while offering fire and hygiene compliance.

8. Clean Rooms

Industries such as pharmaceuticals, biotechnology, and electronics use PUF panels to build airtight, contamination-free clean rooms. These panels integrate seamlessly with HVAC systems to maintain strict air purity standards.

9. Soundproof Partitions

Thanks to their superior acoustic insulation, PUF panels are widely used for soundproof partitions in conference halls, studios, and commercial complexes, helping create quieter and more productive spaces.

⚙️ Conclusion

PUF sandwich panels are no longer just a construction trend — they’re a technological advancement that aligns with modern demands for speed, sustainability, and performance.

From green buildings to industrial complexes, these panels are redefining how we think about durability, insulation, and energy efficiency.

If you’re planning your next industrial, commercial, or prefab project, choosing PUF sandwich panels is not just a smart decision — it’s an investment in the future of construction.